Pallet Break Down

Psssst… this post *might* contain affiliate links: see my disclosure here.

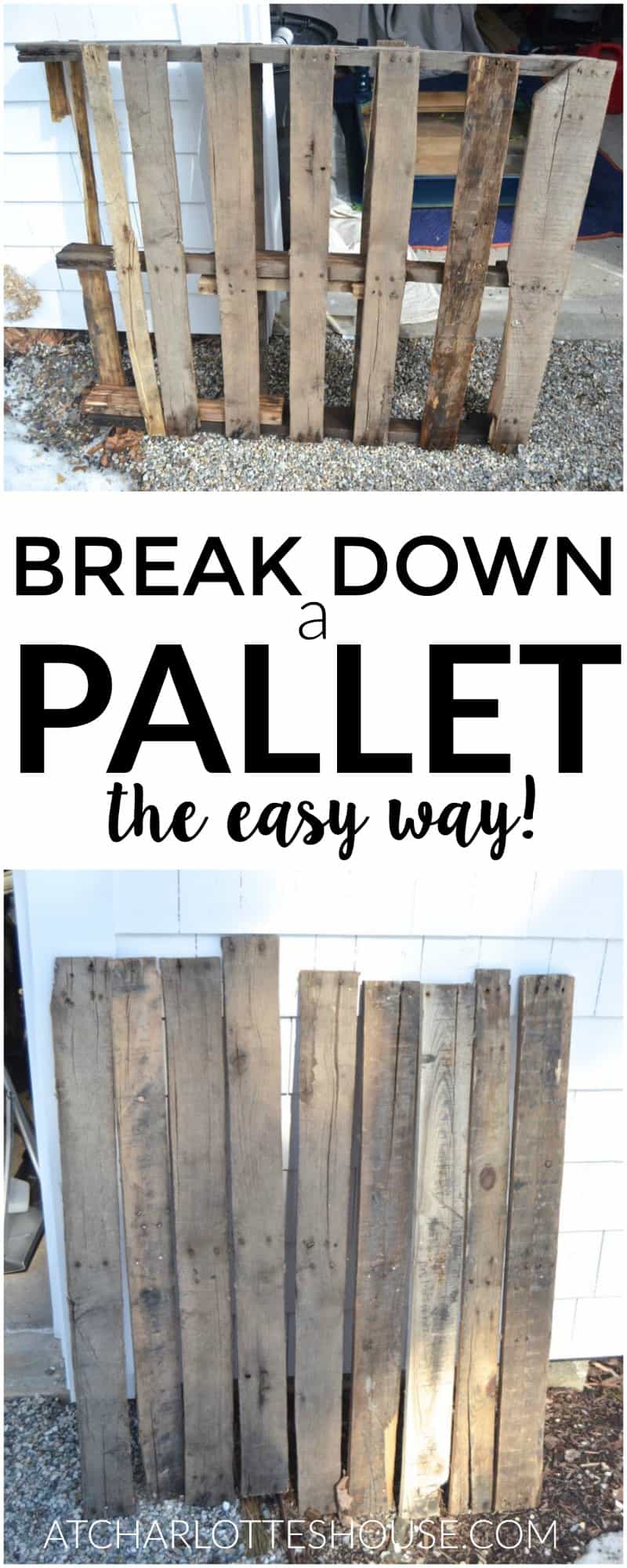

How to Break Down a Wooden Pallet

Wooden pallets can be a great source of free lumber with a wonderful patina, but breaking the apart can be tricky!

I will personally deliver a batch of chocolate cake pops, an arm knitted scarf and a washi taped spring duckling if anyone can provide me with a “Pause” button for this week. I just need an extra day or two. Anyone? Bueller? Shucks. Before we jump in to today’s pallet-palooza, I want to WELCOME ALL MY NEW READERS! Thank you SO much for subscribing and joining the At Charlotte’s House chaos… er, fun! For those of you on social media, you can follow me on Facebook, Instagram, Pinterest and Twitter…. yeah, I know… it’s a lot. I LOVE comments so introduce yourself, let me know where you’re from, your favorite boy band or even what color you thought that dang dress was. I’ll do my best to keep you mildly entertained and you *might* even learn a little something once a month or so. Today? I’m talking pallets. Specifically, how to take apart a pallet so you can actually do cool things with the wood! (Full materials list with affiliate links at the end of the post!)

Shop my favorites!

How to break down a wood pallet. The easy way.

I have a blogging confession to make. I’ve never worked with old wooden pallets. Pallets are the bread and butter for lots of great DIY projects but for whatever reason, I’ve never earned my pallet stripes. For the Restaurant Redesign, we’ve tried to bring in lots of weathered wood details from the floor to the colors to the accessories. There’s a small area right when you walk in that is currently underwhelming so I wanted to make this little space much more of a statement. (Reminder that this is the BEFORE picture…)

I put out an SOS on Facebook and, jackpot… one of my friends had an old pallet she’d been trying to get rid of. The hardest part of working with a pallet is getting at the actual wood. I made a video that talks about ways to dismantle a pallet. But if you’re at work or not in the mood for another video of me with my head cropped out of the shot, then I shared the narrative below. Disclaimer: I’m 26 weeks pregnant with the belly of Kate Gosselin so mobility is affected here, folks.

Some pallet projects use the whole structure of the pallet but more often than not, it’s the slats of wood that are the goal. If you don’t care about preserving the length of the boards, you can use a circular saw and simply cut the wood in between the frame leaving the nailed bits in place. I wanted to maintain the length of each board if possible so I was stuck trying to remove each piece from the frame itself. Which meant going to battle with the dozen plus nails in every board.

Some pallets use soft pine wood so it’s worth trying to pry the boards loose with a crowbar. My pallet was NOT soft and it was ooooold, so the slightest prying was cracking and breaking the boards. No bueno. Next technique involves heavy artillery but is actually super simple once you have the right tools. You’ll need a reciprocal saw and a blade intended for demo work or metal. You’ll still want the crow bar or a hammer because your goal is to slide the saw between the boards and the frame so you’re ONLY cutting the nails themselves. To make room for the blade, it’s probably necessary to pry the wood up a few millimeters.

Once you can sneak your blade in, it just takes some gently coaxing to get the blade through each nail. As always, make sure you’re wearing protective eyewear, gloves if you want, and have the blade moving away from your body.

All in, I’d say it took an hour max to get at all of the boards on this pallet. So not the easiest, but far from the hardest. Update: Since I’ve written this post, I’ve had people suggest this tool. I’ve never used it, but folks say it makes pallet break down easy so I wanted to share as another option.

With boards arranged and aligned, I cut them all to size and screwed in two cross beams to hold the boards in place. The pallet wood was fairly uneven in width so the cross brace is tight in some places and a little loose in others. Next I sanded. I didn’t go crazy with the sander, but I did want to smooth out any splintered edges and even out the tone of the stained boards just a bit.

Here’s what I was making with this pallet wood! A wonderfully fun new sign for a restaurant I was helping to redesign. See the full restaurant reveal HERE!

Materials Needed to Break Down a Pallet

I’ve never worked with the wood from a pallet. I’d like to try though! It’s really helpful you’ve shared how you managed to get it apart!

I hadn’t either, Corinna but… I must say I’m in love with that aged patina! I think there are more pallets in my future. 🙂

Good vid and blog for pallet newbies Charlotte.

A reciprocal saw is an excellent way, especially if someone wants to keep the nail heads as part of the patina look.

Another way and highly suggested if someone’s going to be doing lots of pallets is to buy a pallet breaker. The specially designed tool makes the job easy and fast.

Question:

your rope 7 artwork: what did you use to fasten the rope to the boards?

Excuse the all caps. It was a default setting on the comment page that I couldn’t change.

Hi there! Thanks! And yes… I heard about the pallet breaker. Almost got one for a recent project. 🙂 Those are little rope brackets that I found at the same place where I bought the rope! I wish I could find a link, but it doesn’t look like I shared them anywhere.

Thanks for the reply Charlotte.

I’m looking for something to fasten rope to wood and those look perfect.

Are you able to remember anything more about them or the name?

I Googled rope bracket But got a million results.

Anything more specific would help.

Many thanks. Have a great day.

I think I bought them from the rope place. See if any of these work: https://www.knotandrope.com/collections/decorative-hardware

Don’t waste your time with the pallet breaker

Thanks so much for the link love, Charlotte! Can’t wait to see your finished pallet piece. I already know it’s going to be amazing because…well…it’s you. Also, I love your post intros. You always do such a great job of welcoming your readers. And for the record, I saw white and gold! All the way!

HAHA, thanks! I was so baffled by the whole dress thing. LOVE your pallet headboard, btw… I know that’s not the one I shared, but it looks amazing in the space!

I started working with pallet wood this year. I have made some nice pieces of art. It’s not always easy but it is satisfying in the end.

Yes! Pallet wood is such a wonderful resource… wonderful texture and patina and FREE!

I worked with palets for return Deposit. An had a few busted up ones i COULDN’T return so i rebuilt. One technique first id build a table from palets much like a raised garden with PALETS.

Id rest the working palet on top .

It SAVEs the back from bending. Then I’d get my hi speed hand grinder with a metal cutting disk. . Looks much like a grinding disk but very thin. Then id go between the two pieces of wood an cut ,its easer to lift the wood a little but sonetimes you have too many nails. If the woods too hard then the reciprocating saw called a Sawzall use with a metal cutting blade like the young lady DOES.I wanted to add the grinder because it made easy work on dificult spots. An sometime I’D have to cut the board with a skill saw just short of the end of the board eliminating the nails an holes they leave . Be carefull with THESE tools , they been known to bite back. ALSOPalets are made from exotic woods. Even wood that OUTLAWed here in the us…. That wood can be saved an sold to furniture builders. NOw that wood has caused me many blades an brused thumbs an a bunch of language a sailor would blush. I came accros ebony once an i burned OUTMy old skill saw. Good luck an hope this can add to your post.

Ihave a pallet remover no crowbar etc if you need to see it i would need a mobile number & i can send it a photo of it ok

PS. I forgot to MENTION a tool that i learned about after my time with pallets, its called the deck wrecker! Its a time saver . Its about 5ft long with a claw on the END Slip under the plankthe back rests on the beam ( skids ) an pry up . The 5 ft handle is secret, the crowbar lacks plus no hammer to persuade the crowbar good luck!

Thanks so much! I’ll look into this!

I use a reciprocating saw too. Invest in 8-12″ blades. You can get them at any of the big stores like Lowes and in Michigan, Menards. Cuts down the time of cutting the nails because you can cut an end at a time instead of just one nail at a time. I cut down 12 pallets in a few hours. Getting help to hold the pallet is wise too.

Great tips. Thanks!

This is perfect! Thank you so much for sharing. We are going project crazy right now and have a bunch of pallets we want to use. After destroying a couple, it was good to find your post. We’re going to try a few design projects and see if we can’t use some pine planks as replacements for our floor boards in order to refinish our hardwood floor. Thanks again!